It is the main functional feature of the entire LOMANCO® ventilation turbine. Stable construction consists of reinforced specially shaped blades and two special bearings.

Purpose: The head produces a vacuum, constantly sucking the air from the space below it.

They are here to provide the necessary power of the LOMANCO® ventilation turbine thanks to a specially developed aerodynamic shape. The blades create the most effective support surface for winding and allow for a large twisting movement. The blade resistance thus ensures the most effective transmission of wind power to the rotary part of the turbine. The individual blades are directed to maximize the underpressure of the LOMANCO® ventilation turbine. The blades have grooves produced at their outer edge that increase the supporting surfaces while allowing the continuous drainage of the water outside the turbine body.

Even the LOMANCO® ventilation turbine has a heart and thus bearings. The turbine contains two bearings. For the turbine to provide the highest performance, it is necessary that both bearings allow free rotation of the head with minimal friction. Bearing is the most valuable element of the entire turbine.

Bearing contains

For the LOMANCO® ventilation turbine bearings, a teflon housing is used that perfectly resists high summer and winter temperature differences. No other bearings can withstand both thermal and mechanical stresses in the long term.

Purpose: The bearings are completely closed and therefore no maintenance is absolutely necessary throughout their service life. The bearings are silenced at the same time as the Teflon sleeve, which is again a rarity in the turbine category.

LOMANCO® owns a patent for these unique bearings and is the only turbine manufacturer in the world to use these bearings on its product (under the LOMANCO® WhirlybirdTM).

Lomanco®, through experience, demonstrates in many long-term professional studies at the most important universities that its bearings are irresistible by its durability.

It is formed by profiled arms that provide high resistance to the entire LOMANCO® ventilation turbine even in extremely high and windy winds at speeds of over 200 km/h.

Purpose: It is very important that this construction is made up of one material (profiled aluminum structure) because it only ensures a balanced function at high load and does not damage it due to the incompatibility of the materials. In addition, the aluminum construction does not age and does not bend over time as opposed to steel or plastic.

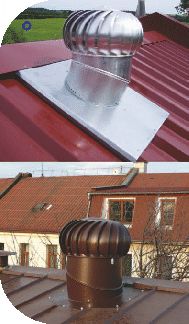

Angularly adjustable joint of the LOMANCO® ventilation turbine (0 ° to 45 ° except of the VP8 and GT12) plays an important role in the installation of the turbine into a sloping roof. By adjusting the joint exactly to the required angle (roof gradient), it ensures that the rotating head is always horizontal.

Meaning: This ensures that the two main bearings are evenly distributed and thus their service life can last for decades.

The element is suitable for installing the LOMANCO® ventilation turbine into flat (unprofiled) roofing, preferably shingles. The bases are also standardized for all common roofing profiles and their material composition.

Purpose: The base is always delivered to maximize the ease of installation of the LOMANCO® ventilation turbine and at the same time ensure perfect connection to the roof for decades.